🔒 Quality Assurance: Built on Certification, Backed by Control

At H.P. Fasteners (JFL India), the concept of quality assurance transcends a mere department; it is the fundamental operating principle governing our entire end-to-end manufacturing process. Our fastening solutions are meticulously engineered not just to fulfill regulatory requirements, but to serve a greater purpose: protecting your essential machinery, significantly reducing long-term service costs, and fundamentally safeguarding your brand image in demanding sectors like automotive, construction, and electronics. Our commitment is proven through the implementation of robust controls, significant investment in advanced technology, and a deep-seated culture of process mastery guided by decades of hands-on industry experience.

Proven Quality Results: Specific, Measurable Guarantees

We eliminate uncertainty by offering specific, measurable guarantees regarding product performance and supply chain reliability, ensuring peace of mind for your operations. A single rusted fastener poses a significant risk, potentially leading to machine failure, warranty claims, and substantial financial losses amounting to lakhs. To counteract this critical risk, our fasteners are treated for superior corrosion resistance and are backed by a steadfast guarantee of enduring 1500+ hours in the Salt Spray Test. Furthermore, our investment in advanced process automation, particularly the utilization of high-precision Optical Sorting Machines, allows us to meticulously detect and instantaneously eliminate any dimensional or surface defects. This technology is key to maintaining our uncompromising goal of 100% defect-free supplies reaching your facility. Finally, we understand that supply chain reliability is as crucial as product quality, which is why we maintain a proven track record of 98.79% on-time delivery, ensuring your assembly and production schedules remain consistently intact.

In-House Capabilities: Total Quality Process Control

We distinguish ourselves from manufacturers relying heavily on external processes by developing strong, comprehensive in-house facilities that ensure total control over the entire quality chain. This integrated approach means that every critical stage of the fastener’s creation is managed and monitored directly by our skilled technicians and sophisticated machinery. Our facilities include a fully equipped Tool Room for precision tooling and rapid prototyping , an in-house Heat Treatment Facility ensuring that specific material grade, strength, and hardness requirements are met internally without quality compromise , and a sophisticated Quality Control Laboratory dedicated to exhaustive testing and material verification. Crucially, our own Surface Finishing Facility allows us to achieve and guarantee the highly specific corrosion resistance levels we promise, maintaining independence and control over the finish quality.

Engineering Partnership and Defect Prevention

Our commitment to quality starts long before the machine is turned on, treating every customer relationship as an engineering partnership built on foresight and transparency. We actively work to mitigate common procurement mistakes through collaborative processes refined by over 30 years of industry experience. This includes starting with joint discussions with your engineering team to fully understand the application and motive behind customization, ensuring perfect alignment from design concept to final delivery. To eliminate issues like missing specifications and the costly blunder of fitting failures, we secure complete drawing approvals before production and subject every customized fastener to a rigorous physical fitment check before development begins. This proactive, detail-oriented approach guarantees that we deliver 100% reliable customized fasteners—components that are built to deliver, built to last, and built specifically for your success.

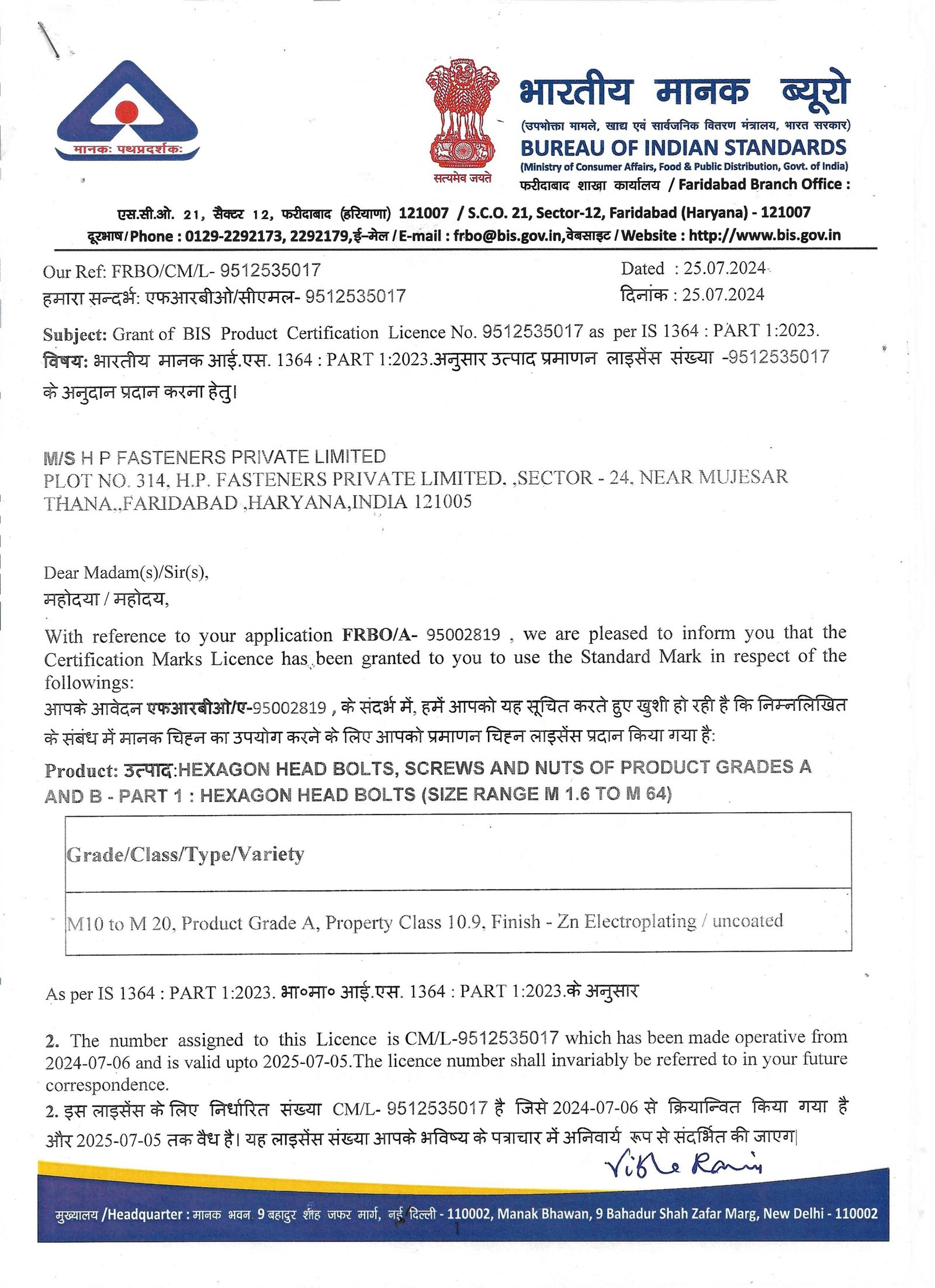

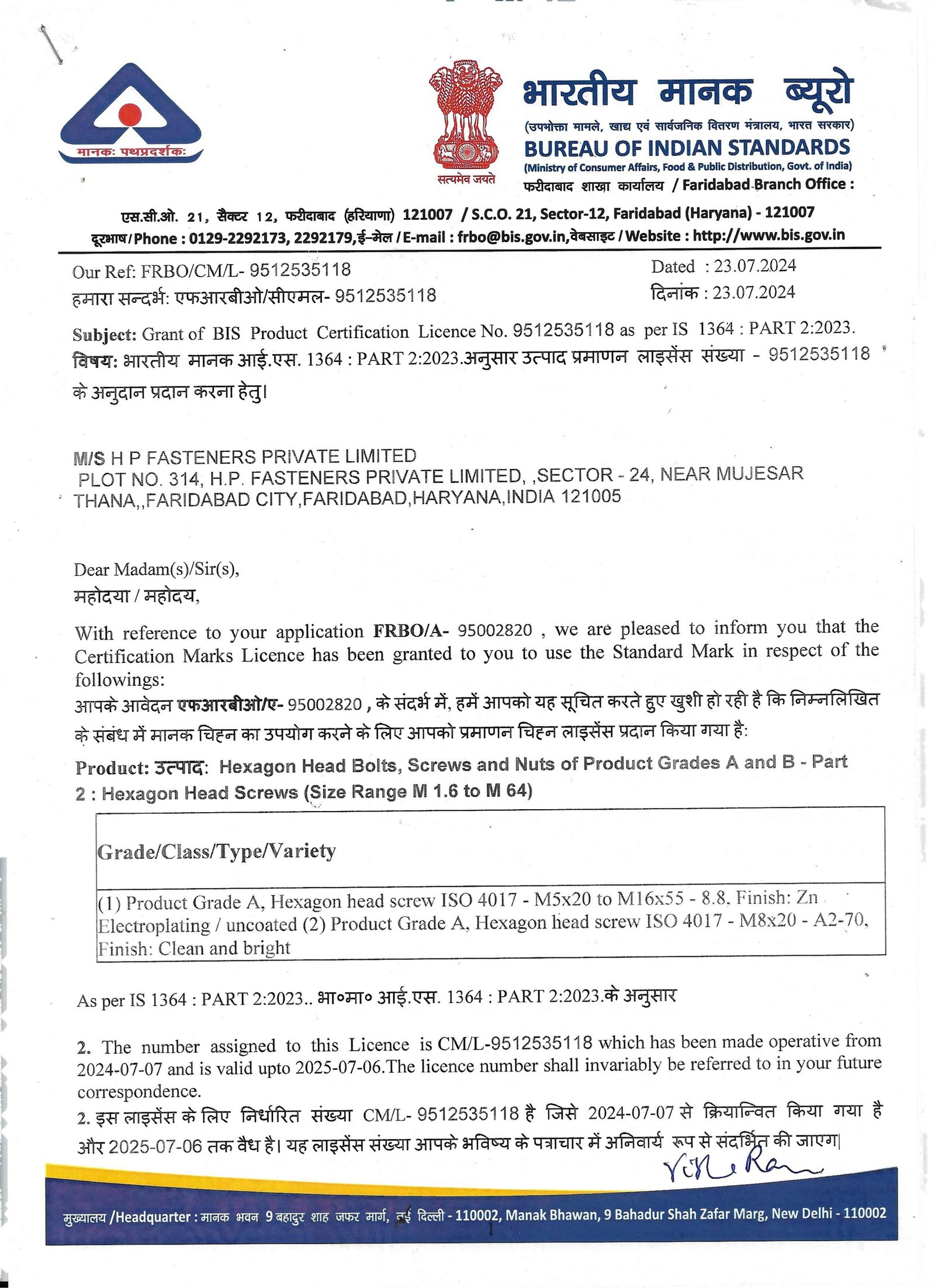

Global Certifications & Automotive Standards

We adhere to the strictest global and industry-specific benchmarks, ensuring every fastener is produced under rigorous process controls and sustainable practices.

Ready to experience world-class quality?

Schedule a meeting or even a visit to our state-of-the-art plant in Faridabad to witness our manufacturing excellence and quality processes firsthand.